Membranes, or DAE (pressure equalization element), are an important part of certain part designs. These membranes have an important function in maintaining a healthy pressure inside the part, making it integral to the safe and proper function of that part in the field.

Many products rely on membranes, including electrical parts in automotive vehicles (converters, steering control units, radar sensors, etc.), consumer devices such as cellphones and smart watches, products with a water-tight housing, and more.

Differences in pressure place a heavy load on the parts and their components and can cause damage to a part, such as deformation and leaks in joint seams, bondings, seals and plug connections. If the components leak, for example, water can penetrate and quickly destroy electronics within a housing.

Since these membranes are relied on to ensure the proper and safe functioning of a part, these membranes must be specifically quality tested during the manufacturing process.

What is a membrane?

Membranes are usually thin, flat materials with a diameter of approximately 3 to 30 mm. They act as a pressure equalizing system within a leak-tight part. For example, when heat is generated

within a sealed part/housing—either from natural heat generated by electronics, a damaged  electronic component causing heat increase, or from the temperature of the outside environment—this creates pressure (or negative pressure, in the case of colder temperature environments) inside the part. This pressure needs a way to escape so it does not damage or destroy the part. A membrane acts as a one- or two-way ventilation system in order to let this pressure out, while still maintaining the “tightness”, or integrity, of the leak-tight part. Sometimes these membranes are designed to burst at a defined pressure, often seen in lithium-ion batteries, for example.

electronic component causing heat increase, or from the temperature of the outside environment—this creates pressure (or negative pressure, in the case of colder temperature environments) inside the part. This pressure needs a way to escape so it does not damage or destroy the part. A membrane acts as a one- or two-way ventilation system in order to let this pressure out, while still maintaining the “tightness”, or integrity, of the leak-tight part. Sometimes these membranes are designed to burst at a defined pressure, often seen in lithium-ion batteries, for example.

How do you test the function of a membrane in a manufactured part?

Generally, a membrane test, or diaphram test, combines a leak test with a subsequent functional test of the diaphragm. If the leak test is assessed as passed (OK), the functional test of the diaphragm is started.

For the functional test, the test specimen is vented for a specified time, then the measurement phase begins. This phase measures the pressure increase (or decrease, when testing for negative pressure) flow from one cavity into the other within the part.

If the pressure increase is within the set permissible limit values, the test is deemed to have been passed and is recorded as OK.

Obtain ultimate accuracy and deeper insights with innomatec’s membrane testing approach

innomatec’s test process is unique in that our functional test checks for two factors; whether there is in fact a membrane present, and whether there is a possible membrane defect based on the test limits set (ie. Double membrane, broken membrane, etc.).

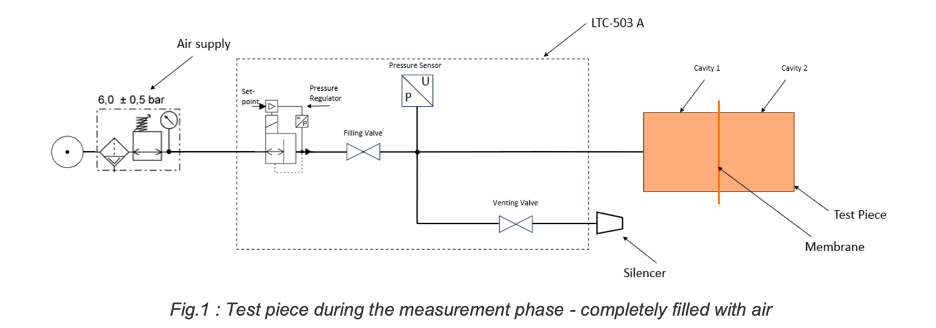

As shown in the next figure, the LTC-503 fills the entire product according to the test specifications for the housing. This first step ensures that the products outer shell is sealed properly.

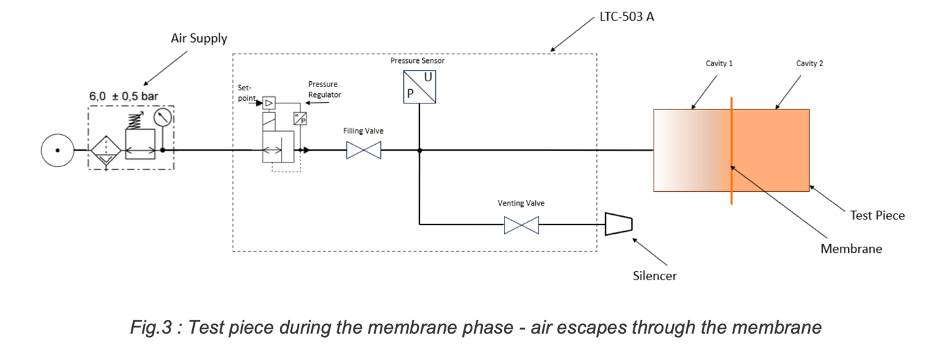

Once the integrity of the housing has been proven, the LTC-503 lowers the pressure on one side of the membrane. The LTC achieves this by opening the venting valve for a short time. As shown, in the next illustration, the pressure on one side of the membrane drops while the pressure on the other side remains high.

Because of the pressure difference between the cavities separated by the membrane, air flows through the membrane to equalize the pressure. This process causes a pressure change in the cavity connected to the LTC-503’s pressure sensor. The LTC-503 analyses the pressure change and evaluates if the membrane’s function is present/correct or not.

Interpreting the results for insights:

- If the membrane permeability is too high, the pressure of both cavities drops instantly if the venting valve is opened. This could be a signal of a missing or faulty membrane.

- A membrane with poor permeability will prevent air to pass according to the specification. In this scenario no pressure increase can be measured in the cavity connected to the pressure sensor. This could be a signal of a double membrane (improper insertion).

- If an optimal membrane is installed properly, the pressure in the cavity connected to the pressure sensor will drop while the venting valve is opened and the proper pressure change is detected (within the set test limits), due to the air passing the membrane for pressure equalization. This is an OK (passing) part.

The following graphic provides a detailed overview of the membrane test phases and the corresponding pressure curve.

Membrane testing functionality in an economical, entry-level leak tester

Membrane testing is an option available on the new LTC-503!

Membrane testing is an option available on the new LTC-503!

This leak test machine is built for ultimate accuracy and flexibility, offering an easy, economical way to perform various leak tests and functional tests—all in one instrument!

NEED A MEMBRANE TESTING SOLUTION? OUR TEST EXPERTS ARE HERE TO HELP!